Polyzme

Environmental innovation in polyethylene and polymers

Polyzme Tech is a market leader in enzyme technology for polyethylene and other polyolefins certified to ISO 17556 for biodegradability in soil. Our exclusive plant-based enzyme, combined with our proprietary process, is the only known peptide and enzyme technology that will completely biodegrade polymers, leaving no trace. Our product biodegrades standard polymers when in contact with soil and waste streams.

Our enzymes make plastic truly recyclable, biodegradable and compostable. There is an improvement in weight, density and production costs. It is based on an enzymatic technology that is a complex of nine main ingredients — all derived from vegetable by-products.

When the enzymes are infused into the plastic, the surface changes polarity — a catalyst for microbes to attach to the plastic. The result is natural biodegradation.

The technology can be adapted to many plastic types, and can even enhance the strength of original material. This cuts the need for large amounts of plastic. The active enzyme is infused in nominal concentrations to activate biodegradation. Cleaner, greener, and cheaper than currently less sustainable alternatives.

This technology has received funding from the European Union’s Horizon 2020 and innovation programme.

- Reduction in plastic weight. Less plastic is required.

- Reduction in hazardous substances. Our enzymes are 100% natural, and leave no trace in the soil.

Environmental innovation in polyethylene and polymers

Polyzme Tech is a market leader in enzyme technology for polyethylene and other polyolefins certified to ISO 17556 for biodegradability in soil. Our exclusive plant-based enzyme, combined with our proprietary process, is the only known peptide and enzyme technology that will completely biodegrade polymers, leaving no trace. Our product biodegrades standard polymers when in contact with soil and waste streams.

Our enzymes make plastic truly recyclable, biodegradable and compostable. There is an improvement in weight, density and production costs. It is based on an enzymatic technology that is a complex of nine main ingredients — all derived from vegetable by-products.

When the enzymes are infused into the plastic, the surface changes polarity — a catalyst for microbes to attach to the plastic. The result is natural biodegradation.

The technology can be adapted to many plastic types, and can even enhance the strength of original material. This cuts the need for large amounts of plastic. The active enzyme is infused in nominal concentrations to activate biodegradation. Cleaner, greener, and cheaper than currently less sustainable alternatives.

This technology has received funding from the European Union’s Horizon 2020 and innovation programme.

- Reduction in plastic weight. Less plastic is required.

- Reduction in hazardous substances. Our enzymes are 100% natural, and leave no trace in the soil.

Objectives

Knowledge

Promote research, education and innovation on sustainable practices.

Improve

Switching from conventional plastics to biodegradable plastics will improve environmental sustainability.

Support

Promoting a circular economy where waste products are reused, repurposed and regenerated rather than being disposed of.

Innovation in polyethylene and polymers

Polyzme Tech is a market leader in enzyme technology for polyethylene and other polyolefins with a range of organic agricultural products and packaging certified to ISO 17556 for biodegradability in soil. Our exclusive plant-based enzyme is the only known peptide and enzyme technology that 100% biodegrades polymers biologically.

Certification

Over the last 15 years, with the help of our technical partners who have more than 20 years of experience in the enzyme industry, we have tested and certified their effectiveness according to various international standards.

| Standard | Description |

|---|---|

| IS014855 | Compostable packaging (includes ecotoxicity, heavy metals, biodegradation) |

| ASTM D5988 | Biodegradable in soil |

| IS017556 | Biodegradable in soil |

| ASTM D7209 | Plastic recycling |

| AIMPLAS | Biodegradable in soil |

Our team

Carl Schafer

Chief Executive Officer

Gonzalo Fernández S

Chief Operating Officer

Jay Rai

Sales Director

Gonzalo Fernández G.

Executive Director

Julio Carazo

Sales Executive

Casos de estudio

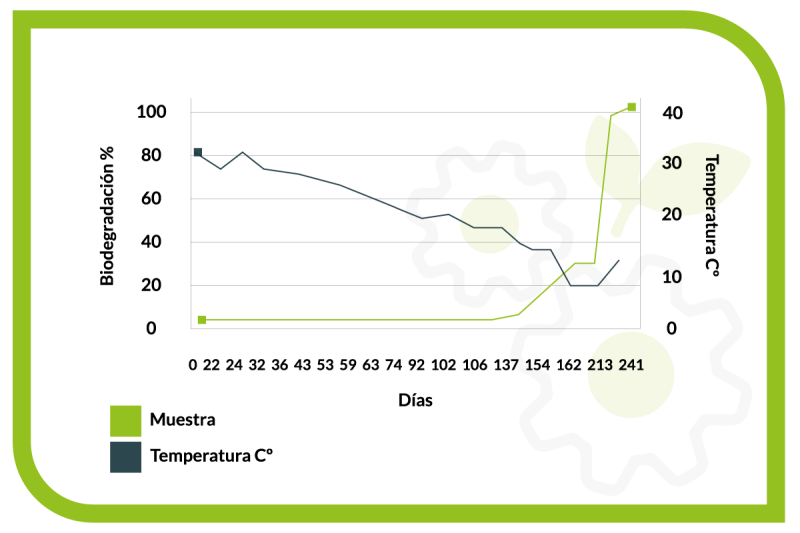

Especial importancia tienen las especificaciones de la película, las condiciones del clima, el suelo, calor y humedad que afectarán a la duración, la velocidad y la tasa de biodegracación dentro de los parámetros de la norma.

Día 1

Día 100

Día 210

Día 240

*También tenemos la posibilidad de biodegradación durante 90-120 días y > 12 meses.

Las cifras que aparecen a continuación muestran el aumento del rendimiento con el uso de Mulch Film.

Este estudio ha sido publicado por el Departamento de Agricultura y Cooperación del Ministerio de Agricultura del gobierno de la India en el “Practical Manual on Plastic Mulching”.